Acoustic Analyzer

Acoustic Analyzer (SX-NVA Acoustic Analyzer) is an advanced multi-channel sound acquisition and analysis device, available in both 4-channel and 8-channel configurations. It features an intuitive interactive interface that not only optimizes basic noise monitoring functions but also provides a wide range of analytical tools for professional users. This makes it suitable for various complex acoustic environments and measurement needs.

The acoustic analyzer excels not only in audio signal acquisition but also in high-precision vibration signal collection. Whether used for environmental noise monitoring, equipment fault diagnosis, or precision engineering measurements, this device can meet a variety of needs. By integrating multiple sensing technologies, the acoustic analyzer achieves more comprehensive signal capture and analysis, providing more reliable and accurate test data.

Core Technology Highlights

By integrating multiple sensing technologies, the Acoustic Analyzer achieves more comprehensive signal capture and analysis, providing more reliable and accurate test data.

Multi-Channel Support

The Acoustic Analyzer offers versatile multi-channel support, providing 4 or 8-channel BNC interface connections. It is suitable for various application scenarios and can flexibly accommodate different signal acquisition needs.

Customizable Settings

The device supports custom configurations via PLC, TCP, and other protocols, allowing users to personalize settings based on specific application needs, thereby enhancing the flexibility and practicality of the equipment.

Built-in Analyzer Software

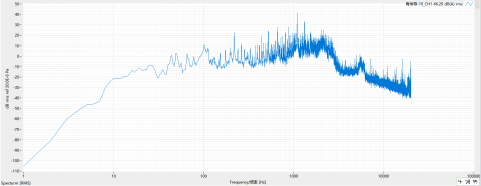

The device comes with a variety of built-in analysis software, supporting customizable analysis functions. It allows users to quickly adjust and configure settings based on different analysis requirements, improving analytical efficiency (including AI algorithms for detecting abnormal sounds).

Ease of Use

The user interface is intuitively designed, making operation simple and flexible. This allows users to quickly get started and efficiently complete tasks, making it suitable for users of all skill levels.

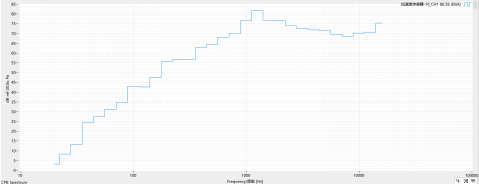

High-Frequency Signal Analysis

The Acoustic Analyzer is suitable for multi-channel analysis of high-frequency signals, offering precise measurements and efficient data processing to meet the demanding requirements of advanced acoustic analysis.

Multiple External Interfaces

The Acoustic Analyzer is equipped with multiple external interfaces, supporting flexible connections with various devices and sensors.

The main functions of the acoustic analyzer

Acoustic analyzer hardware configuration

| Processor | 12th Gen Intel(R) Core(TM) i3-12300T 2.30 GHz | Intel |

| Memory | 16G-DDR4 | Kingston |

| Motherboard | H610 | Colorful |

| Solid state | 2TB-NVME | Kingston PCIE4.0 |

| Earphone | 3.5mm stereo socket (audiometry channel one signal) | |

| Operating temperature range | Temperature: -10 ℃ ~ 50 ℃, humidity: 20% ~ 90% | |

| Output interface | 4 USB2.0, 3 USB3.0, wireless wifi, Bluetooth | |

| Fan | IIntel/Others | Original 1700 |

| Power supply | 300/500w | Full model |

Scenario application

Auto parts

The noise test box is mainly used to test the noise, vibration, NVH, etc. of automobile parts. Tested products include engines, car seat drives, displays, car actuators, air conditioning systems, etc. Through the noise test box, automobile manufacturers can carry out effective noise control and optimization during the design and development process, improving the overall quality and user experience of the vehicle.

3C electronics field

The noise test box is mainly used to test the noise, vibration, sound pressure level, etc. of 3C products. Tested products include smartphones, headphones, speakers, computer fans, tablets, micro motors, etc. Through the noise test box, 3C electronic product manufacturers can effectively monitor and control product noise to ensure their competitiveness in the market and user satisfaction.

Medical device

The noise test box is mainly used to test the noise, abnormal sound, sound quality, etc. of medical equipment. Products tested include ventilators, dental equipment, surgical machinery, monitors and more. With noise test chambers, medical device manufacturers can ensure that their products do not produce excessive noise when in use, thereby improving patient comfort and device reliability.

Home appliance field

Noise test boxes are mainly used to test noise, vibration, sound quality, etc. in the field of home appliances. Test products include air conditioners, vacuum cleaners, refrigerators, washing machines, etc. Through the noise test box, home appliance manufacturers can effectively control product noise to ensure their competitiveness in the market and user satisfaction.